Training

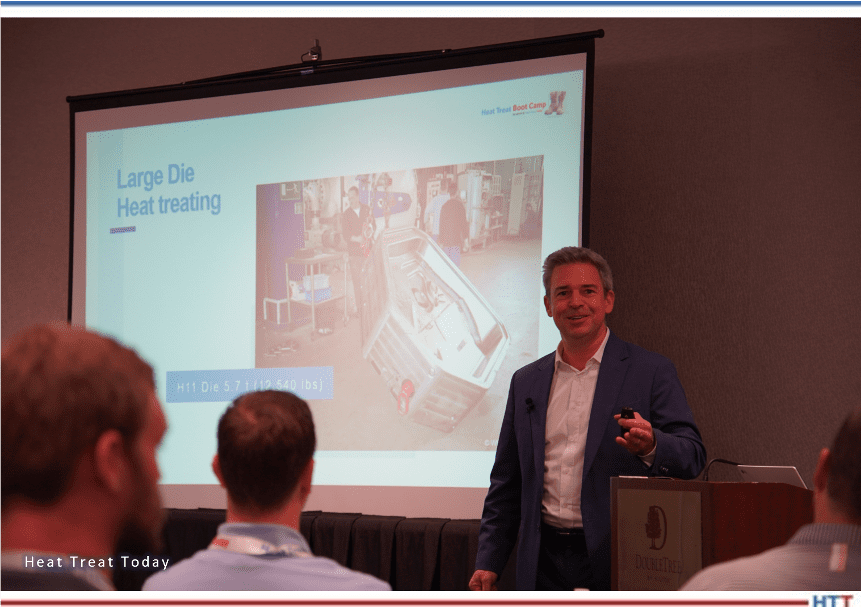

Made a good investment of time and funds by attending The Heat Treat Boot Camp held last week in Pittsburgh, PA with thorough presentations given by Doug Glenn, Founder/Owner/Publisher of Heat Treat Today and Thomas Wingens, President of Wingens Consultants. Subjects included Market & End Products, Heat Treat Processes & Materials and Heat Treat Industry Players (Equipment and Components Manufacturers with over 40 members in attendance). Numerous opportunities availed themselves to discuss potential ADSORPTION APPLICATIONS for Gas Recovery, Purification and Recyle.

Great technical presentation! Really enjoyed learning from your experience.

Thank you for taking good care of one of our new employees, Jalen Dennis, at the Heat Treat Bootcamp.

He said he really enjoyed it and learned a lot. As soon as he returned, he said he’d like to take part in more training. It’s encouraging that his time at Heat Treat Bootcamp inspired him to pursue more knowledge to further his career.

Wingens Consultants provide heat treat and metallurgical classes.

These include the Heat Treat Today BootCamp and a course in Metal Additive Manufacturing (AM) and Post Processing for Optimized Properties and Performance at the headquarter of ASM International.

To learn more or be alerted when new classes are offered, please fill out the form and read the class information below.

Training ASM International

Metal Additive Manufacturing (AM) and Post Processing for Optimized Properties and Performance, August 26-28, 2024

Dates: Aug 26, 2024 – Aug 28, 2024

Venue: ASM International World Headquarters – Materials Park

Location: Novelty, OH, 44073, United States

Instructor: Mr. Chad Beamer, Dr. Virginia Osterman, Mr. Thomas Wingens, and Dr. Andrzej Wojcieszynski

This course delivers a thorough exploration of Metal Additive Manufacturing (AM) and Thermal Processing, encompassing historical progression, AM processes, classifications, and applications. It addresses the topics of powder manufacturing, handling, and characterization, printing processes and testing of printed parts, standardization and qualification processes, safety protocols, and provides a detailed examination of post-print processes, including Hot Isostatic Pressing (HIP) and heat treatment, equipment, testing standards, applications, and recent advancements.

Classroom: $2,200.00

Member Price: $2,000.00

Training Heat Treat Bootcamp

Players

Who are the major suppliers in the North American heat treat market?

Find out who supplies air & atmosphere furnaces, vacuum furnaces, salt bath furnaces, fluidized bed furnaces, induction heating equipment, burners & combustion systems, heating elements, controls, instrumentation including thermocouples, atmospheres & industrial gasses, quenching fluids & systems, insulation/refractories & ceramics, cooling systems, alloys & fabrications, castings, hot zone, vacuum pumps/valves/gauges, induction coils & power supplies/transformers, materials characterization & testing equipment.

Products

What are the products sold by the Players?

What are the most popular heat treating processes and why are they performed? There’s no heavy metallurgy, but enough to understand the why and how of each processes

Markets

What are the major end-user markets and companies that utilize heat treating and why? Markets like aerospace, automotive, medical, energy, general mfg, and many, many more.

Materials

What type of materials are being heat treated and why? Learn about:

- Iron

- Different types of steels including low-carbon & high-carbon steels, low-alloy & high-alloy steels, tool steels and specialty steels

- The various types/grades of aluminum and how they differ

- Titanium

- Other metals like copper, brass, nickel, zinc, tungsten, etc.

Future Trends

What type of materials are being heat treated and why? Learn how heating treating impacts:

- 3D printing/additive manufacturing

- Hot isostatic pressing

- Hydrogen combustion

- Electrification of heat treating equipment

- Sustainable heat treat technology