Thermal Process Technology

Adjusting physical properties

Heating metals can have a profound impact on their properties, ranging from changes in mechanical strength and electrical conductivity to alterations in magnetic behaviour and corrosion resistance. These effects are a result of complex interactions at the atomic and microstructural levels.

Thermal Processes are adjusting the material to the perfect properties and pushing their capabilities to the maximum. Over the past decades, Wingens Consultants has helped over 40 commercial and captive heat treat companies and departments improve their heat treat processes and heat treat recipes, and also assets.

Whatever the issue, our experience is extensive and includes heat treatments for simple low-carbon steel components, alloy steels, stainless steels, tool steels, non-ferrous metals, and exotic steels such as stainless tool steels, and many specialty and proprietary alloys.

Thermal Process Consulting

Metallurgical specialties

- Hydrogen Metallurgy: HDH, Descripitation, Reduction

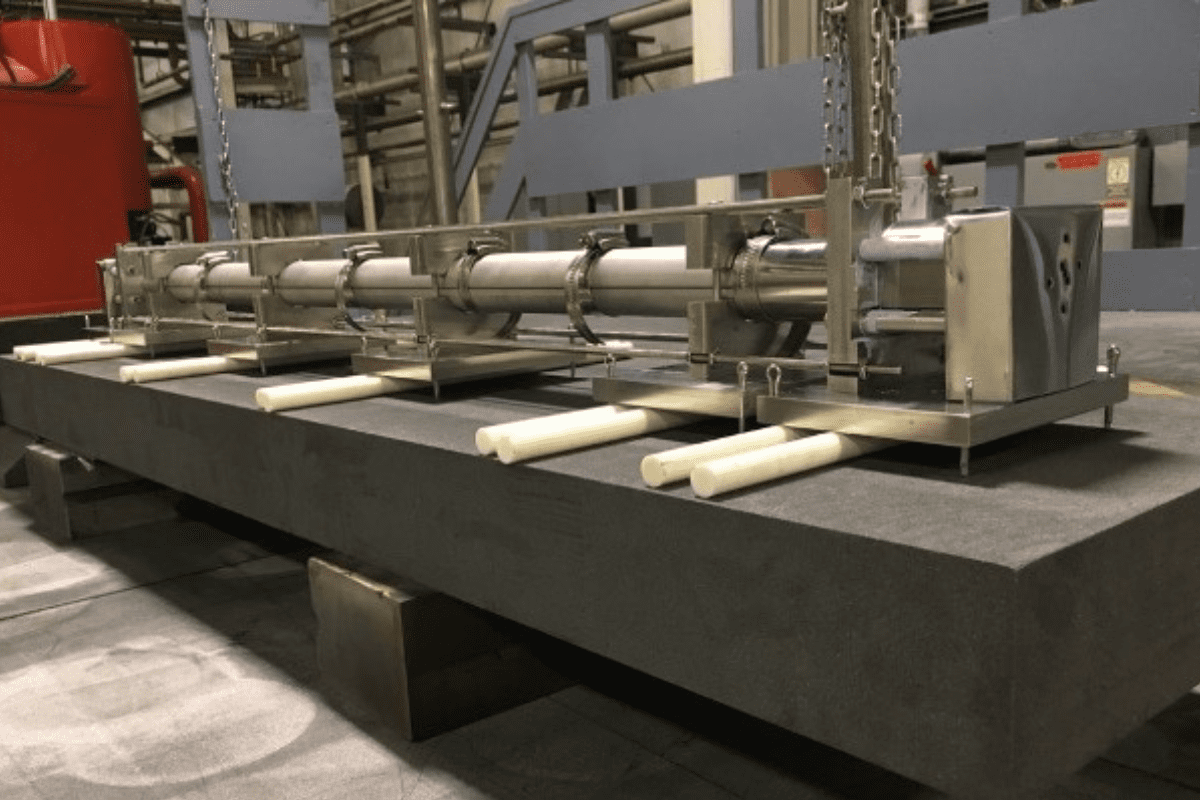

- Powder Metallurgy: Sinter, Debind-Sinter, HIP

- Diffusion Metallurgy: Brazing, Diffusion Bonding, Boronizing, LPC, FNC

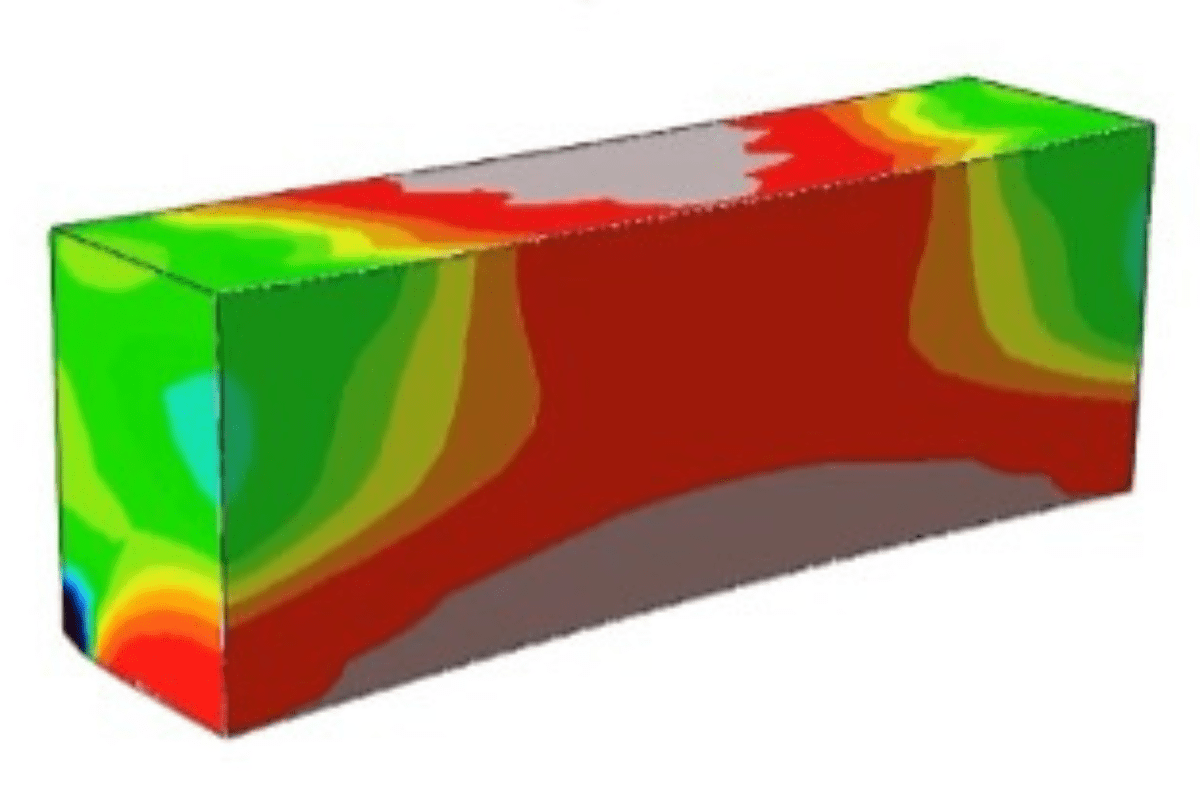

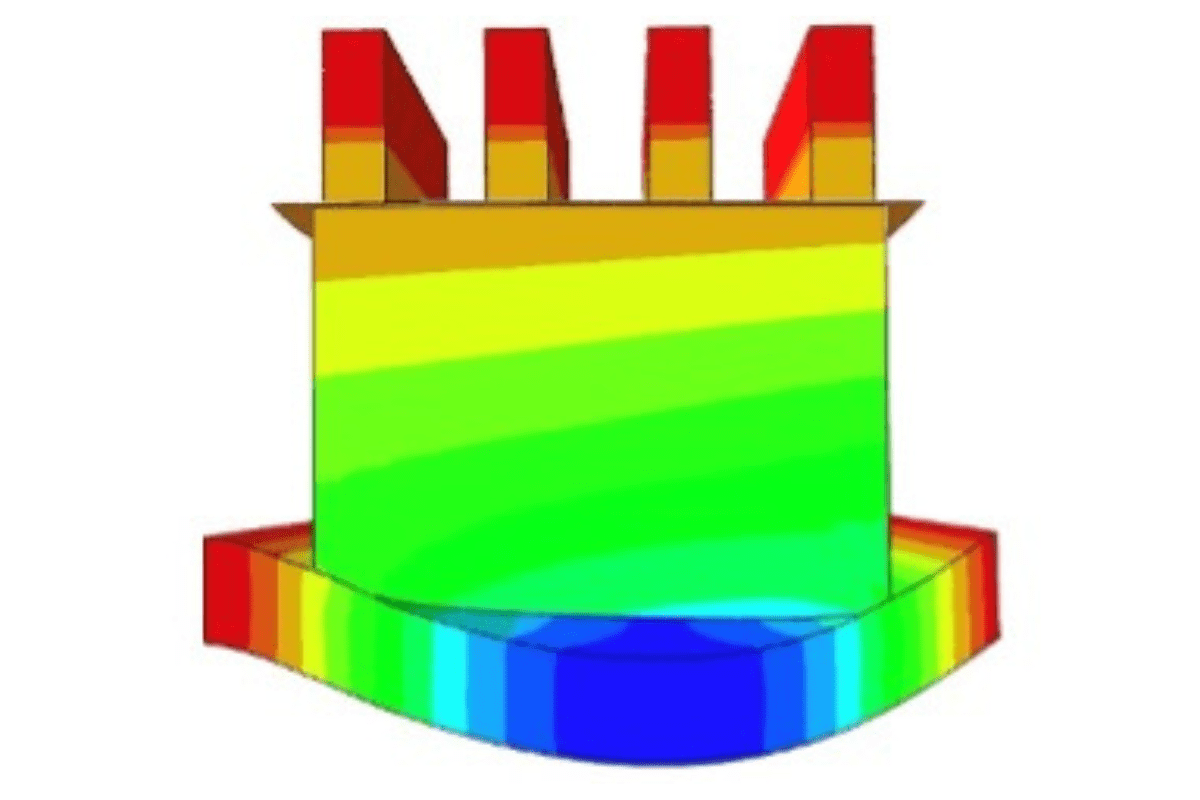

- Process Simulation and Modeling

Powder Metallurgy of specialty Materials

- Ti, T a, Nb, W, Zr, for Energy storage, Battery Materials or Nuclear applications

Our process development assistance includes:

- Atmospheric and Vacuum (LPC) Carburizing/ Carbonitriding

- Nitriding/Nitrocarburizing/FNC

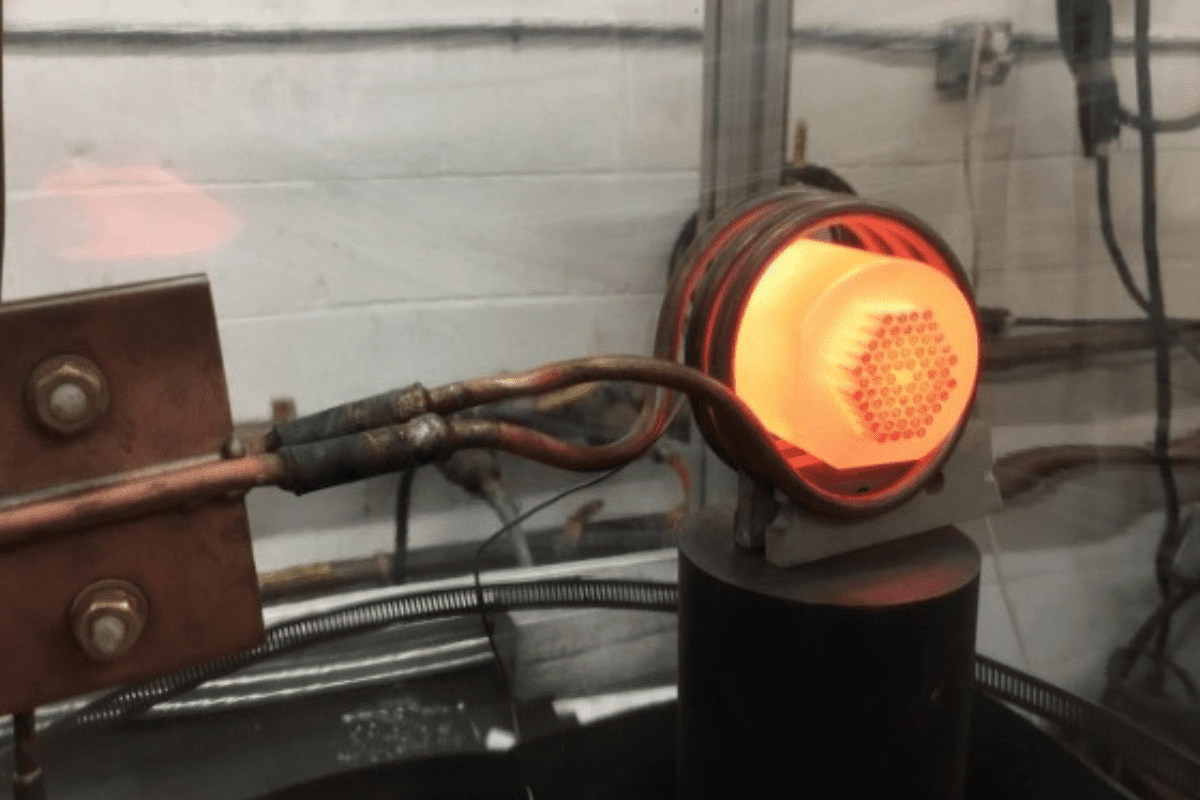

- Induction/Flame Hardening

- Annealing/Normalizing/Stress Relieving

- Metal Heat Treating and hardening

- Stainless and Tool Steel heat-treating

- Bainitic hardening / Marquenching

- Brazing and Diffusion Bonding

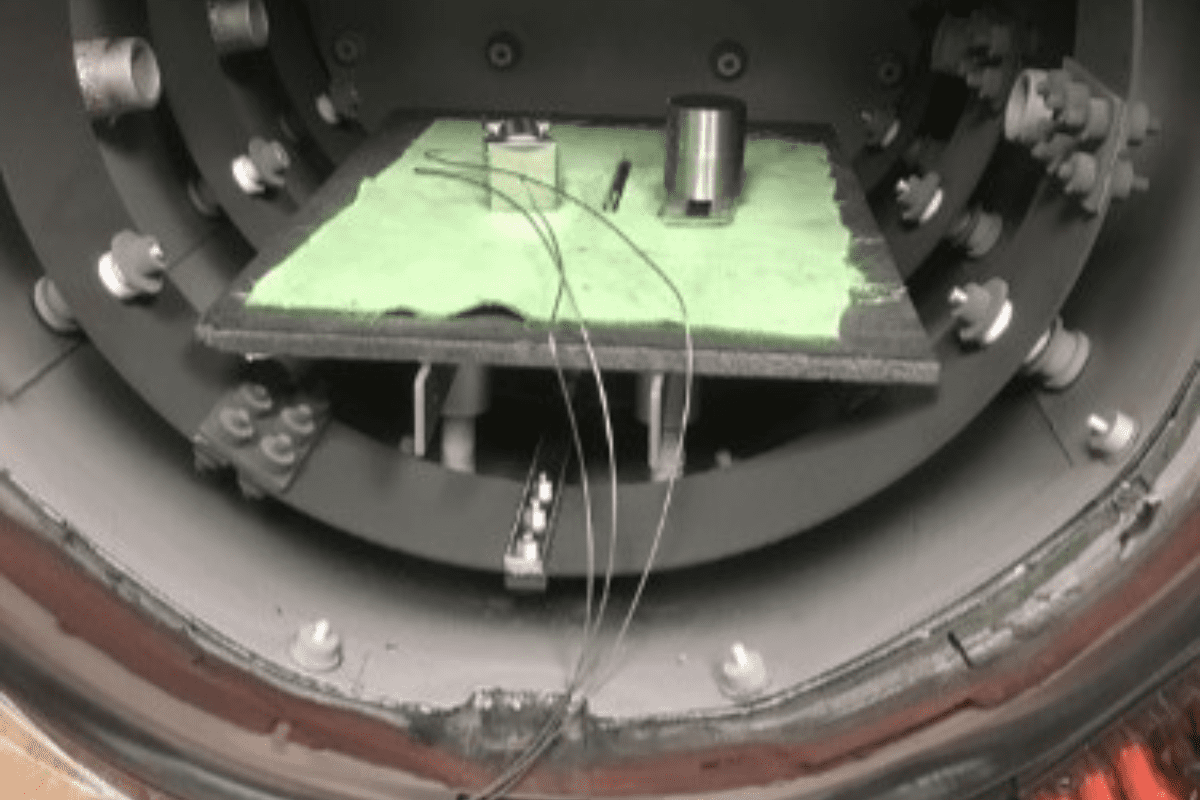

- Spark Plasma Sintering (SPS), Hot Pressing, Hot Isostatic Pressing (HIP), HIP-Cladding

- Surface technologies (Plating, coating, PVD, CVD, boronizing, TDF, galvanizing