furnace technology

Furnace Consulting – Selection process

We are dedicated to providing our clients with the best furnace equipment and partners tailored to their specific needs. With over 35 years of hands-on experience in selecting and operating various thermal process equipment, we understand the significance of uptime and availability for successful and profitable business operations.

Our furnace engineering support is typically divided into three phases:

- Initial phase for process investigation and scope finding

- Purchasing phase involving specification, competitive bidding, and partner selection

- Project management & commissioning

Furnaces play a crucial role in various thermal processes, adding substantial value to the manufacturing value chain. This value is achieved through a physical-chemical treatment that significantly enhances material performance, rather than relying on alloying or mechanical treatment. For these processes to be reliable and reproducible in large industrial volumes, the equipment must consistently perform proven process parameters 24/7. When well-designed and properly serviced by a reliable OEM, a furnace can have a lifespan of 30 to 60 years. However, a faulty design can lead to low availability and premature decommissioning, resulting in substantial loss of capital and production.

As such, selecting the right furnace vendor is more of a long-term partnership. It’s crucial to choose a vendor that is reliable and focuses on proven processes, as we have witnessed several furnace OEMs going bankrupt due to failed specialty projects. Unlike machining equipment, furnaces operate under hot conditions 24/7. The uptime and availability of such capital-intensive equipment is critical for the successful and profitable operation of a business.

Phase 1: Furnace Vendor Audit

Most client processes are not as refined or mature.

It is crucial to question process parameters such as volumes, times, and gas flows, and define a solid process parameter window to accurately specify the scope. Simply put, before we begin the selection process, we need to know what we are looking for. With thousands of furnace manufacturers in the industry, each targeting different markets and having different areas of expertise.

During the initial phase, we are evaluating and reviewing various furnace vendors who could potentially meet our standards and specifications. Our aim is to select two top vendors with proven references for these specific requirements and who are willing and capable of contributing their extensive knowledge to this project. We require vendors with similar furnaces already in operation for many years, which we often repurpose for our proprietary process. We are not considering vendors who need to learn during this project.

After conducting trials, we will define a specification that will guide us to the purchasing phase. We will also assist in obtaining the necessary permits.

We have specific guidelines and requirements for our purchasing agreements, and we will communicate these to two vendors simultaneously until the final agreement is signed. This approach helps us avoid unexpected surprises during the negotiation process. Our main objective is to establish a reliable, long-term partnership with the vendor, especially since we develop proprietary processes that are crucial to keep confidential.

Phase 2: Furnace Purchase

The next step is to purchase the furnace, which involves specifying the requirements, competitive bidding, and selecting a reliable and experienced partner. Furnaces are crucial in the manufacturing value chain, and their reliability and reproducibility are essential for large-scale industrial processes. A well-designed furnace can last up to 60 years with proper maintenance, while a faulty design can lead to premature decommissioning, causing significant losses in capital and production.

With defined parameters and a specification in hand, we engage in discussions with two vendors simultaneously until the purchasing agreement is finalized. This is important to avoid surprises during the final negotiation phases.

It’s not only about pricing and terms, but also about establishing a long-term partnership with a trustworthy vendor, as very proprietary processes are developed which need to be kept away from competition for as long as possible.

We are currently using this method for eight active specialty metal furnace projects in the USA, and we have successfully implemented it with clients worldwide for the past twelve years.

Phase 3: Furnace project management & commissioning

Once the purchase order is placed, we will ensure open and clear communication among all stakeholders and audit vendors involved in the manufacturing/assembly process to ensure that the quality and timely delivery meet specifications.

Changes in design and scope can sometimes lead to a better outcome, but they need to be carefully controlled and managed to avoid unexpected cost increases and delays.

We will support plant P&ID design and coordinate a PHA/HAZOP study between the vendor and the client if required. Installation and commissioning on-site must be coordinated with auxiliary equipment of other vendors and contractors. All equipment must meet code and comply with local standards. We will be present at the SAT (Site acceptance test) for the final acceptance of the equipment and will hand it over to the production team.

When selecting the right furnace vendor, we prioritize building a long-term partnership with a reliable and experienced OEM.

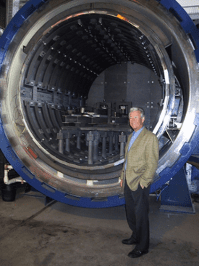

Bespoke Furnace Concepts

At Wingens we develop for your bespoke thermal processes the most economical, energy efficient and dependable furnace concepts. We do not invent, we reconfigure proven and established furnace systems and apply them for your processes in the best possible way.

Case Study

Our client previously used four different furnaces for their manufacturing process, each for a different thermal process. They wanted to scale up manufacturing and reduce their CO2 footprint.

We proposed using a well-established modular furnace concept from the aerospace industry to handle all four processes. The result was a single furnace that could handle all processes, with increased equipment utilization, 50% lower capital cost, 40% less power consumption, and 30% shorter cycle time.